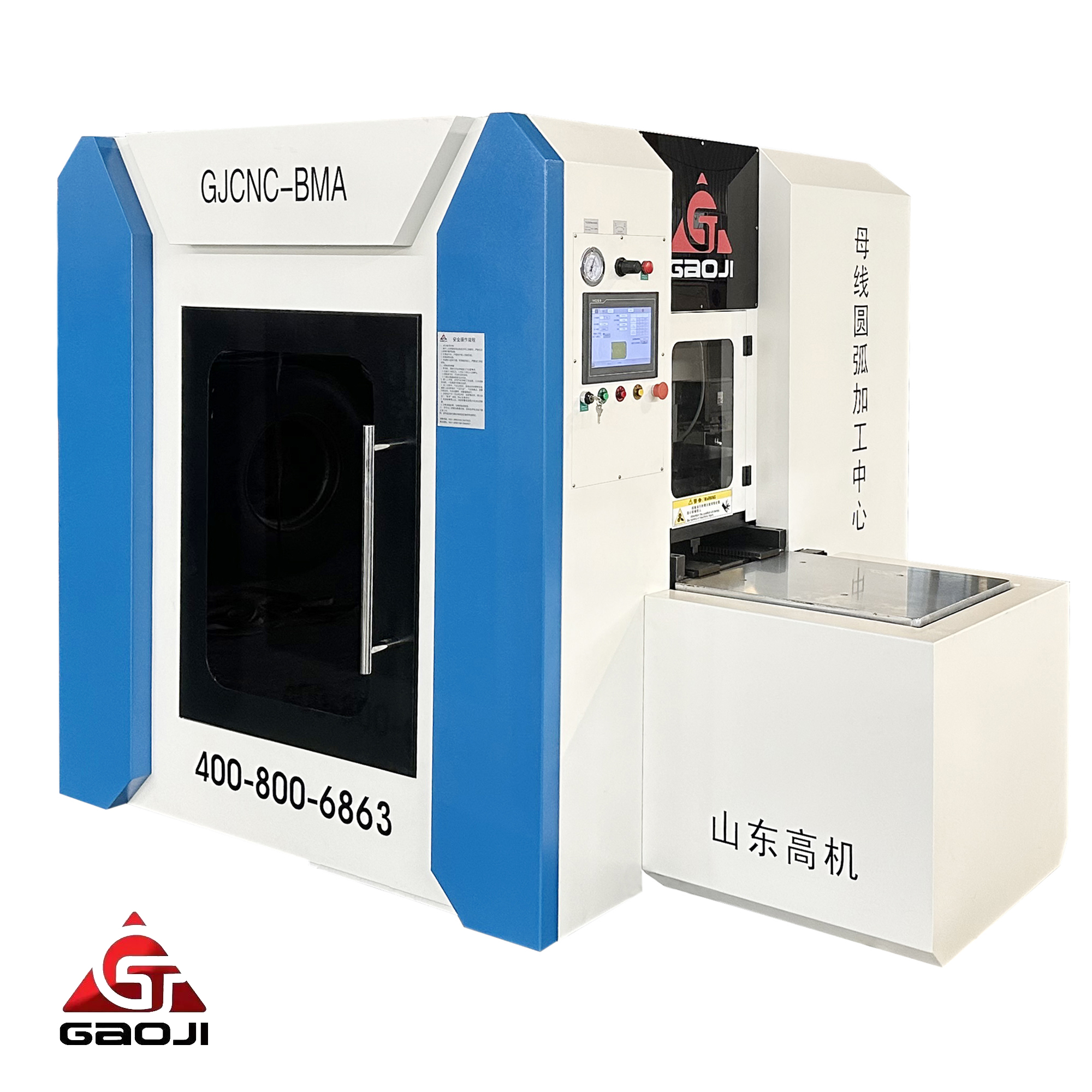

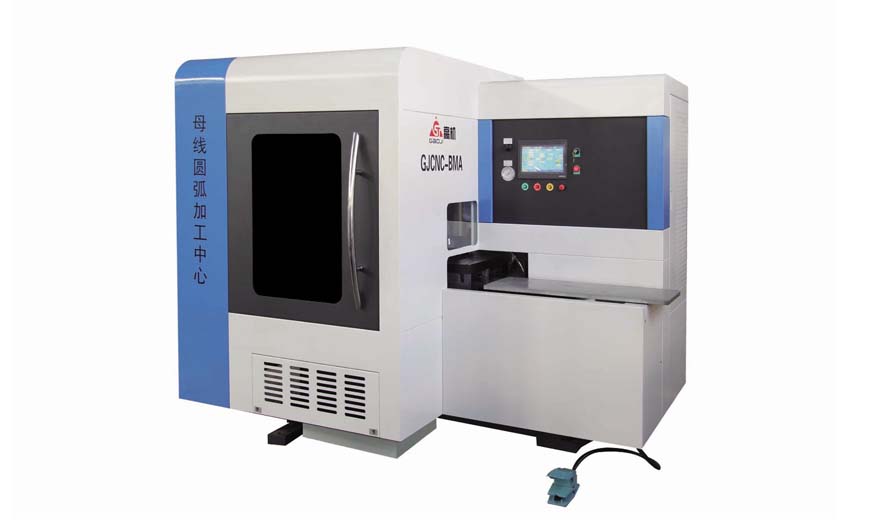

Ixabiso eliphantsi le-CNC Automatic Copper High Effiency Processing Bending Punching Cutting Machine Busbar Arc Machining Chamfering Machine

Ngoku sinezixhobo eziphambili. Iimpahla zethu zithunyelwa eMelika, e-UK njalo njalo, zithandwa kakhulu ngabathengi ngexabiso eliphantsi. I-CNC Automatic Copper High Effiency Processing Bending Punching Cutting Machine Busbar Arc Machining Chamfering Machine, Sifuna intsebenziswano enkulu nabathengi bamanye amazwe ngokuxhomekeke kwinzuzo efanayo. Nceda uzive ukhululekile ukunxibelelana nathi ukuze ufumane ulwazi oluthe kratya!

Ngoku sinezixhobo eziphambili. Iimpahla zethu zithunyelwa eMelika, e-UK njalo njalo, zithandwa kakhulu ngabathengi bethu.Umatshini weBusbar oZenzekelayo kunye nomatshini weBusbar weCopper, Inkampani yethu ngumthengisi wamazwe ngamazwe othengisa olu hlobo lwempahla. Sinikezela ngokhetho olumangalisayo lwezisombululo ezikumgangatho ophezulu. Injongo yethu kukuvuyisana nawe ngengqokelela yethu ekhethekileyo yezinto eziqwalaselweyo ngelixa sibonelela ngexabiso kunye nenkonzo egqwesileyo. Umsebenzi wethu ulula: Ukubonelela abathengi bethu ngeemveliso kunye nenkonzo engcono ngamaxabiso aphantsi kangangoko.

Iinkcukacha zeMveliso

Umatshini wokugaya ibhasi we-CNC usebenza kakhulu kwi-fillet yokugaya kunye ne-fillet enkulu kwi-busbar. Uvelisa ngokuzenzekelayo ikhowudi yenkqubo kwaye udlulisele ikhowudi kwisixhobo ngokusekelwe kwiimfuno ze-busbar specifications kunye nedatha engenayo kwisikrini sokubonisa. Kulula ukuyisebenzisa kwaye ingasebenza nge-arc yebhasi eluncedo kwaye ibukeka intle.

Inzuzo

Lo matshini usetyenziselwa ukwenza i-sectional arc machining yeentloko ze-busbar ezine-H≤3-15mm, w≤140mm kunye ne-L≥280mm.

Intloko yentsimbi iya kudityaniswa ibe yimo enolwakhiwo oluzinzileyo.

Iikliphu zisebenzisa iteknoloji yokubeka phakathi ngokuzenzekelayo ukuze zicinezele intloko yokucinezela ngcono kwindawo yokuthwala amandla.

Isixhobo sokunyusa sisetyenziswa entlokweni yokucinezela ukuqinisekisa uzinzo lwento yokusebenza, nto leyo enika isiphumo esingcono somphezulu womatshini.

Isibambi sezixhobo se-BT40 esisemgangathweni wehlabathi sisetyenziselwa ukutshintsha iiblade ngokulula, ukuqina okucolekileyo kunye nokuchaneka okuphezulu.

Lo matshini usebenzisa izikrufu zebhola ezichanekileyo kakhulu kunye nezikhokelo ezithe ngqo. Kukhethwe iireyile zesikhokelo ezinkulu ezinomthwalo omkhulu ukuze zinike ukuqina okungcono komatshini wonke, zinciphise ukungcangcazela kunye nengxolo, ziphucule umgangatho wento yokusebenza kwaye ziqinisekise ukuchaneka okuphezulu kunye nokusebenza kakuhle.

Ngokusebenzisa izixhobo zeempawu zasekhaya nezaziwayo kwihlabathi liphela, lo matshini uhlala ixesha elide kwaye unokuqinisekisa umgangatho ophezulu.

Inkqubo esetyenziswa kulo matshini yisoftware yemizobo ezenzekelayo efakwe ngaphakathi eyenziwe yinkampani yethu, efezekisa ukwenziwa kweenkqubo ngokuzenzekelayo. Umqhubi akufuneki aqonde iikhowudi ezahlukeneyo, kwaye akufuneki azi indlela yokusebenzisa iziko lemveli loomatshini. Umqhubi kufuneka afake iiparameter ezininzi ngokubhekisa kwimizobo, kwaye izixhobo ziya kuvelisa ngokuzenzekelayo iikhowudi zomatshini. Kuthatha ixesha elifutshane kuneenkqubo ezenziwe ngesandla kwaye kususa amandla empazamo yekhowudi ebangelwa kukwenziwa kwenkqubo ngesandla.

I-Busbar eyenziwe kulo matshini ibukeka kakuhle, ayinayo indawo yokukhupha amanzi, inciphisa ubungakanani bekhabhathi ukuze kongiwe indawo kwaye inciphisa kakhulu ukusetyenziswa kobhedu.

Ngoku sinezixhobo eziphambili. Iimpahla zethu zithunyelwa eMelika, e-UK njalo njalo, zithandwa kakhulu ngabathengi ngexabiso eliphantsi. I-CNC Automatic Copper High Effiency Processing Bending Punching Cutting Machine Busbar Arc Machining Chamfering Machine, Sifuna intsebenziswano enkulu nabathengi bamanye amazwe ngokuxhomekeke kwinzuzo efanayo. Nceda uzive ukhululekile ukunxibelelana nathi ukuze ufumane ulwazi oluthe kratya!

Ixabiso eliphantsiUmatshini weBusbar oZenzekelayo kunye nomatshini weBusbar weCopper, Inkampani yethu ngumthengisi wamazwe ngamazwe othengisa olu hlobo lwempahla. Sinikezela ngokhetho olumangalisayo lwezisombululo ezikumgangatho ophezulu. Injongo yethu kukuvuyisana nawe ngengqokelela yethu ekhethekileyo yezinto eziqwalaselweyo ngelixa sibonelela ngexabiso kunye nenkonzo egqwesileyo. Umsebenzi wethu ulula: Ukubonelela abathengi bethu ngeemveliso kunye nenkonzo engcono ngamaxabiso aphantsi kangangoko.

Uqwalaselo

| Ubukhulu (mm) | Ubunzima (kg) | Ubungakanani beTheyibhile yokuSebenza (mm) | Umthombo woMoya (i-Mpa) | Amandla ewonke (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Iiparameters zobugcisa

| Amandla kaMama (kw) | 7.5 | Amandla eServo (kw) | 2*1.3 | I-Max Torpue (Nm) | 62 |

| Imodeli Yomphathi Wezixhobo | BT40 | Ububanzi besixhobo (mm) | 100 | Isantya seSpindle (RPM) | 1000 |

| Ububanzi bezinto (mm) | 30~140 | Ubude bezinto ezincinci (mm) | 110 | Ubukhulu bezinto (mm) | 3~15 |

| I-X-Axis Stoke (mm) | 250 | I-Y-Axis Stoke (mm) | 350 | Isantya seNdawo eKhawulezayo (mm/min) | 1500 |

| Iphiko leBhola yeSikrufu (mm) | 10 | Ukuchaneka kwesikhundla (mm) | 0.03 | Isantya sokutya (mm/min) | 1200 |