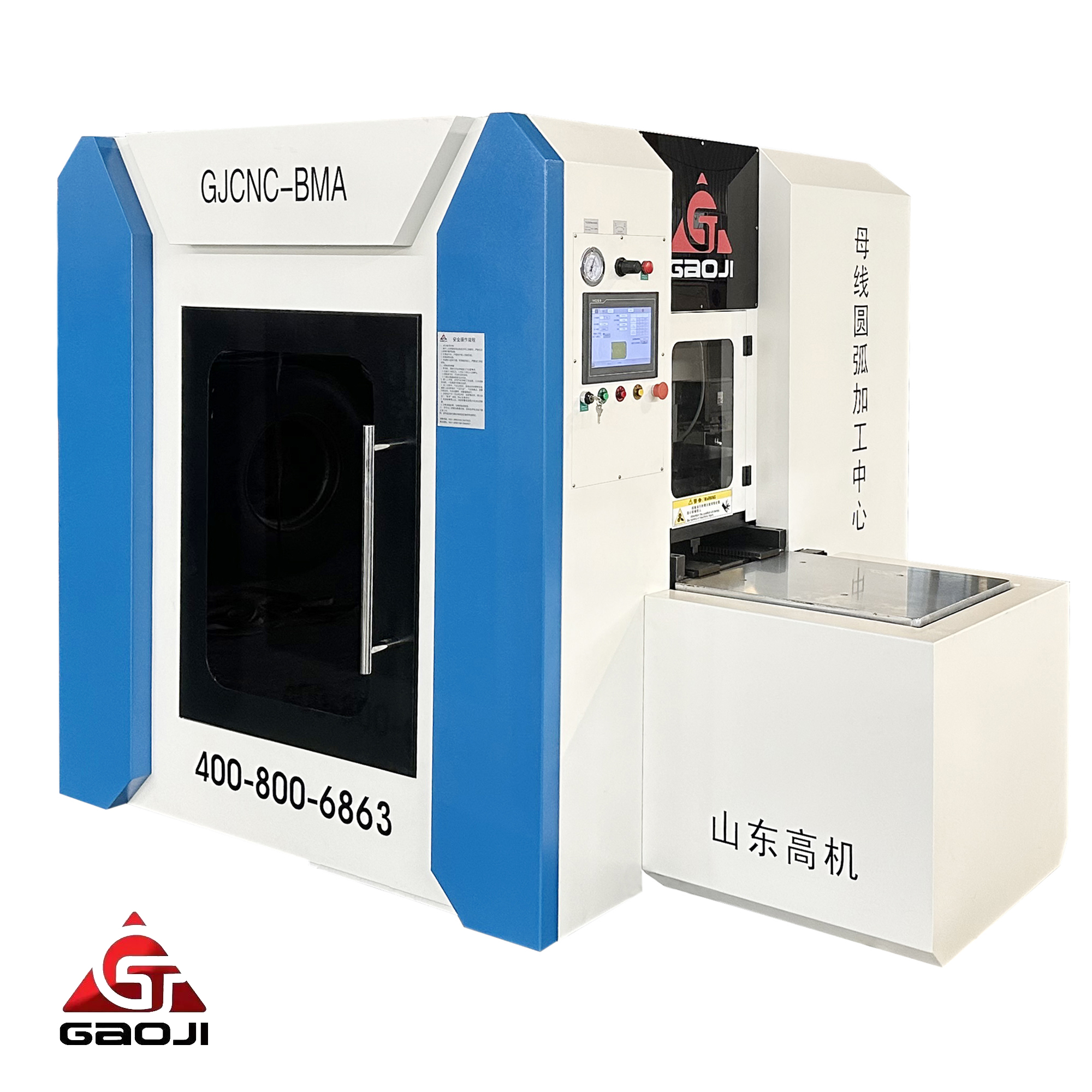

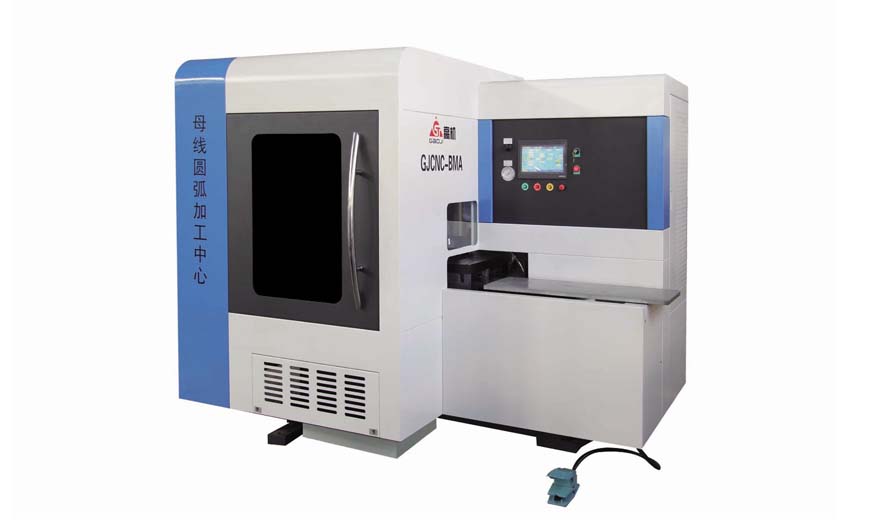

CNC Busbar Arc processing iziko lebhasi bar yokusila umatshini GJCNC-BMA

Iinkcukacha zeMveliso

Umatshini wokugaya ibhasi ye-CNC usebenza ikakhulu kwi-fillet yokugaya kunye ne-fillet enkulu kwi-busbar. Ivelisa ngokuzenzekelayo ikhowudi yeprogram kwaye idlulisela ikhowudi kwisixhobo esisekelwe kwiimfuno kwinkcazo yebhasi yebhasi kunye nokufakwa kwedatha kwisikrini sokubonisa. Kulula ukusebenza kwaye unomatshini oluncedo we-busbar arc ngenkangeleko entle.

Inzuzo

Lo matshini usetyenziselwa ukwenza umatshini we-arc wecandelo kwiintloko zebhasi kunye ne-H≤3-15mm, w≤140mm kunye ne-L≥280mm.

Intloko yebha iya kufakwa kwimilo enesakhiwo esisisigxina.

Iiclamp zamkela itekhnoloji yokuzenzela eseko ukucofa intloko ecinezela ngcono kwindawo yokubeka amandla.

I-booster isetyenziswa kwintloko ecinezelayo ukukhusela uzinzo lwe-workpiece, inika umphumo ongcono wokusebenza.

Isibambi sesixhobo se-BT40 somgangatho wehlabathi sisetyenziselwa ukutshintshwa kwe-blade elula, ukuqina okuhle kunye nokuchaneka okuphezulu.

Lo matshini wamkela izikrufu zebhola ezichanekileyo kunye nezikhokelo zemigca. Umthwalo onzima wesikhokelo sobukhulu besikhokelo sikhethwe ukunika ukuqina okungcono komatshini wonke, ukunciphisa ukungcangcazela kunye nengxolo, ukuphucula umgangatho womsebenzi kunye nokuqinisekisa ukuchaneka okuphezulu kunye nokusebenza kakuhle.

Ukusebenzisa amacandelo emveliso yasekhaya neyehlabathi edumileyo, lo matshini unobomi obude benkonzo kwaye unokuqinisekisa umgangatho ophezulu.

Inkqubo esetyenzisiweyo kulo matshini yinkqubo yenkqubo yemizobo ezenzekelayo ephuhliswe yinkampani yethu, iqonda i-automation kwiprogram. Umsebenzisi akufuneki aqonde iikhowudi ezahlukeneyo, kwaye akufuneki ukuba azi indlela yokusebenzisa iziko lomatshini lemveli. Umsebenzisi kufuneka afake iiparitha ezininzi ngokubhekisa kwimizobo, kwaye izixhobo ziya kuvelisa ngokuzenzekelayo iikhowudi zoomatshini. Kuthatha ixesha elifutshane kunenkqubo ye-manual kwaye isusa amandla empazamo yekhowudi ebangelwa yinkqubo yeprogram.

Uqwalaselo

| Ubungakanani (mm) | Ubunzima (kg) | Ubungakanani beTheyibhile yokuSebenza (mm) | Umthombo woMoya (Mpa) | Amandla Aphelele (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Iiparamitha zobuGcisa

| Amandla ombane (kw) | 7.5 | Amandla eServo (kw) | 2*1.3 | UMax Torpue (Nm) | 62 |

| Imodeli yoMphathi wesixhobo | BT40 | Ububanzi besixhobo (mm) | 100 | Isantya seSpindle (RPM) | 1000 |

| Ububanzi beMaterial (mm) | 30-140 | Ubude obuncinci beMaterial (mm) | 110 | Ukutyeba kwezinto (mm) | 3–15 |

| I-X-Axis Stoke (mm) | 250 | I-Y-Axis Stoke (mm) | 350 | Isithuba esiKhawulezayo isantya (mm/min) | 1500 |

| I-pitch ye-Ballscrew (mm) | 10 | Ukuchaneka kwesikhundla (mm) | 0.03 | Isantya sokutyisa (mm/min) | 1200 |